Phantom Crackle

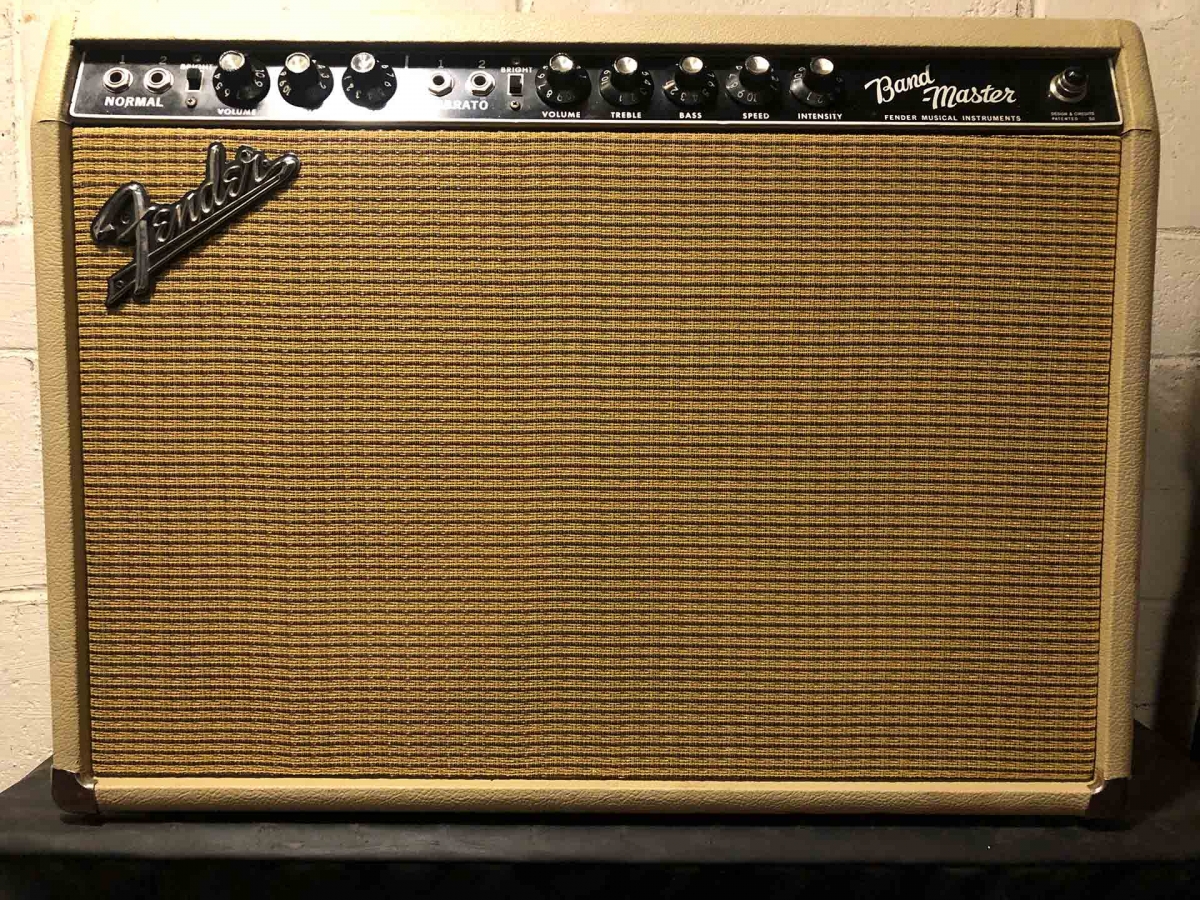

My buddy Ivan uses this combo-ified 1963 Band-Master as his backup. It suffered from a phantom crackle that would only appear after being warmed up for an hour or two. It had been in and out of another shop for over a year, and the problem was never successfully addressed.

The chassis of this amp was put into a third-party 2x10 combo cabinet by the previous owner, and it was getting a little long in the tooth. After more than a year of back-and-forth and missed connections, Ivan finally got it back from the shop, and thought it would be nice to give it a little TLC.

He replaced the grill cloth and re-glued a lot of the tolex. This actually involved a bit of woodworking, too, as the grill cloth originally stuck out proud of the front face of the cabinet. He actually had to move the speaker baffle back a ways to make it consistent with a standard Fender combo amp, and to properly protect the grill cloth.

After all that effort, two hours into band practice the following week, it was a bit disappointing to hear that the original problem still hadn’t been fixed. Rather than send it back into the shop, Ivan decided to leave it in mine—after all, it was already there!

The sound was sort of electrical static/crackling in nature. It was only audible with the standby switch on (not in standby mode), so the power section was the prime suspect. And remember, the amp was fairly quiet until it had warmed up for a few hours.

The best way to troubleshoot stuff like this is to first go for the low-hanging fruit. I turned it on, let it warm up for two hours, then tapped the tubes with a stick. The 7025 preamp tube in the normal channel was very microphonic, but nothing in the power section seemed to make much noise, although the 12AT7 phase inverter was a little crackly.

I powered down the amp, cleaned the tube sockets, and swapped out the microphonic 7025 with a 12AX7. I really wanted to know what the problem was with this amp, and why it out-smarted the other tech for so long. Because I had the luxury of time on this one, rather than just shotgun a bunch of stuff, I thought it would be best to try one thing at a time, test, and repeat.

The next day, I fired up the amp and let it warm up for two hours before I played through it. No crackling! That was too easy. Amps don’t sit on the bench for a year because of microphonic tubes and dirty tube sockets. I was skeptical, but maybe the amp was fixed, and just sat for so long that the tube sockets were corroded again.

Two hours into band practice the following week, the crackle returned. Aha, so we need two hours of actual signal running through the amp to make it sweat.

Now it was time to go a little deeper. For my next trick, I pulled the chassis and set the amp and speaker up on by bench so that I could poke around with the thing powered on. Crackles typically mean loose connections, so I started poking everything with a stick. Tapping various places on the board not only caused the amp to crackle, it also triggered the static/crackling sound that would typically only start after being warmed up. Poking around near the normal channel tone stack seemed to cause the loudest crackling, but so did the board near the phase inverter.

I powered the amp back down and buzzed it out so I could tug on wires and check for shorts in the pre-amp section. Everything seemed to check out.

I fired the amp back up and began poking around again. The crackling was easy to reproduce, but it only loosely seemed to be associated with certain parts of the board. Because it also went away when the amp was in standby, I really needed to dig into the power supply. I powered down the amp again, zapped it, and flipped it over.

Opening the doghouse revealed that all the filter caps had recently been replaced. For the heck of it, I fired the amp back up and began to poke the filter caps. SUPER CRACKLE! Two of the 22MFD caps were really noisy when poked with a stick. I was certain I had found the culprit. The two larger, series filter caps didn’t make any sound, so I left them in place and swapped the others.

This time, when I fired up the amp and poked around, silence. This is the sort of problem that could reasonably be missed by an experienced tech. You don’t generally expect brand new filter caps to be bad. Especially not two of them. I cleaned up the chassis, put it back in the cabinet, and fired it up for a while. It sounded great. No crackle, and dead quiet when I banged on the top. I really thought I had this one nailed.

The following week, two hours into practice, the crackle kicks back in! The amp was quiet when you banged it on the top, but it still had the sporadic electrical static/crackling sound in the background.

For my next trick, I figured I would swap out those two larger series filter caps so I could at least rule them out. I then fired it up and played it for a good two hours to try to get it crackling again. Sure enough, the crackling started, and I began poking around again with my artisan, hand-carved pokey stick.

Nothing changed the crackle. I poked all the coupling caps and tone caps. Nothing. I flipped the standby switch. The crackling stopped. Aha! It’s still the power section. I poked the power tubes. No change. I poked the phase inverter tube: crackle! CRACKLE!

Mother fucker. I remember this tube cracking in my first round of testing, but I wanted test one thing at a time. I swapped it out for a spare 12AT7 Ivan left me with, and boom (boom as in fixed, not exploding tubes). Dead quiet.

Practice the following week was the real test, and I'm happy to report that the amp performed perfectly without a single crackle. To this day, there have been many more crackle-free band practices with this amp!

My take-aways from this repair are that you should never assume a single cause for a problem with a vintage amplifier. For that matter, you should never assume a single problem. It’s easy to forget things from your initial inspection. You should write them down and refer back to your notes. The last big thing: the pokey stick is one of the most important tools on your bench.